Here’s how a large fancy color rough stone cracked during polishing, with a huge loss to the owner

In this article FCRF continues to raise awareness about issues that are generally hidden from the professional public. In a unique achievement, FCRF was able to get hold of a fully documented case in which the polishing of a high value stone went terribly wrong, with photos that illustrate each stage. This is an exceptional opportunity to illustrate the risks that manufacturers face and the possible gloomy outcome.

The 16.56-carat hexagon rough diamond was bought in July 2016 at a diamond auction conducted by a South African diamond producer. The stone had a very strong yellow saturation and was expected to yield a 9.5-carat vivid yellow cushion cut with VS clarity.

The 16.56 Vivid Yellow Rough

The 16.56 Vivid Yellow Rough

Before beginning the polishing process, the stone was thoroughly checked for any internal tension. The findings showed very low tension, indicating it was safe to work on.

Stones are examined for internal stress for two reasons. First, when a manufacturer wants to buy a processing insurance policy, the insurance company needs to determine the risk and the premium size. Second, stones with high internal stress are sometimes planned differently and may not go through a laser sawing process. Generally, rough diamonds are split into two parts to extract a second stone from one of the apexes of the octahedron and increase overall yield.

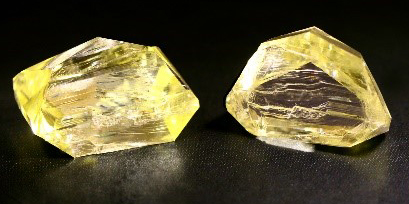

Since this stone showed low stress, it was put into a laser sawing machine, successfully resulting in two parts.

The two parts after the laser sawing

The next step was to begin polishing the larger part.

Starting polishing the crown angels

At a certain point, it was time to form the crown facets. The stone was safely glued to the dop, and the cutter placed the stone gently on the polishing wheel. Knowing that this diamond cost just under a million dollars, he felt a heavy responsibility. Every few seconds, he lifted the stone to inspect the progress with his loop. After a few strokes, he lifted the dop and couldn’t believe his eyes… the clean vivid yellow stone he had seen just seconds before had completely cracked without any warning or sound.

The starting and end point of the crack

“I know it is difficult to comprehend, but it feels as if a patient you are conducting a simple operation on died in your hands. Making the call to the owner of the diamond and letting him know he has lost a great deal of money is even worse,” said the polisher.

“The damage creates an enormous emotional blow. Despite the stone having low internal tension, it cracked due to external factors such as vibrations from uncalibrated polishing wheels, overpressure during cutting, high-speed polishing, or using old tools that don’t hold the diamond tightly. There is no way to reverse it. If you break a very expensive porcelain Chinese vase, you can glue it back together. If you punch a hole in a Rembrandt oil painting, it can be restored. But if you crack a diamond, there is no way to repair the damage,” the owner explained.

At this point, the only way to salvage some part of the investment was to split the stone where the crack is and extract the maximum yield from the pieces.

When a yellow fancy color stone is reduced in size, it loses its color. This is because in a smaller stone, light waves encounter fewer nitrogen molecules than they would in a larger stone. The smaller pieces will generate a much weaker color than the original vivid yellow stone. Consequently, the outcome for the owner is an exponential loss on two counts – smaller sizes and weaker color.

Splitting manually the cracked stone

When a yellow fancy color stone is reduced in size it loses its color. The reason for this lies in the fact that in a smaller stone light waves encounter less nitrogen molecules than they would have in a larger stone. The smaller pieces will generate a much weaker color than the original vivid yellow stone would have shown. As such, the outcome for the owner is an exponential loss on two counts – smaller sizes and weaker color.

The two parts of Rough after splitting the diamond

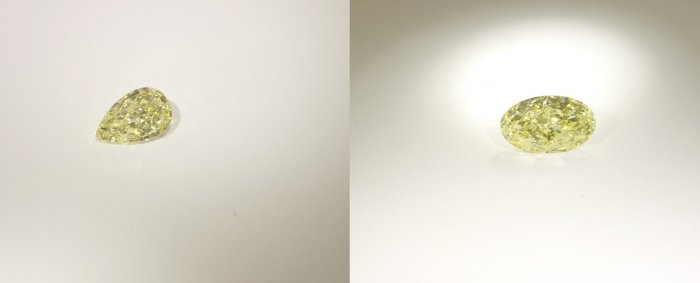

In the end, as seen in the images below, the 16.56-carat rough stone, which was supposed to yield a 9.5-carat vivid yellow cushion, resulted in two “fancy yellow” diamonds of 2 and 3 carats each, valued at one-tenth of the investment.

The end result yielded two Fancy Yellow Diamonds

In conclusion, this case illustrates just one of the many hardships faced by manufacturers of fancy color diamonds. Numerous challenges must be met before a stone is set in a luxurious piece of jewelry such as challenging sourcing, financing marketing and more . Among these, cracking a diamond during the polishing process is one of the most painful and costly setbacks. The importance of maintaining high standards in tools, machinery, and professionalism even when a diamond shows low internal stress cannot be overstated in this delicate and demanding craft.

*Dop – a tool for holding gemstones for cutting or polishing.